SOFTCONSULTING

A team of professionals in the field of engineering

www.softconsulting.az

www.softconsulting.az

SOFTCONSULTING

Many years of experience in the design of gas trunklines

www.softconsulting.az

www.softconsulting.az

SOFTCONSULTING

Qualitative analysis and full report on the work performed

www.softconsulting.az

www.softconsulting.az

Designing

Offshore Platforms

Offshore Overpasses

Field Improvement

Pipelines

Compressor Facilities

Architecture and Construction

Prospecting and Surveying

Energy and Communication Systems

Instrumentation and Automation

Automation and Technology

Projects Economic Asessment

Corrosion Protection

Sanitary Technical Work

Ecology

Designing

________________________________________________________

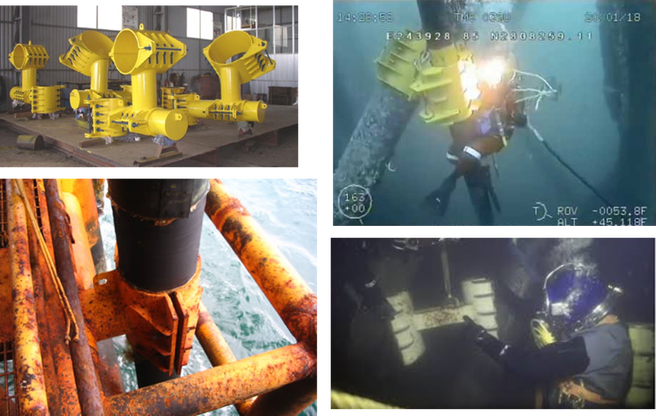

- Analysis of offshore structures

Predict platform or topside behavior with comprehensive analysis including nonlinear, dynamic and impact forces. Use integrated modules to simulate pile-soil interactions and apply wind, wave, seismic, ship impact, dropped objects, and shockwaves.

- Stress analysis in various applications

Integrate structural analysis and pipeline stress analysis by combining modeling, analysis, design, documentation and detailing in a single ISM environment that combines the structural and mechanical industries. Maximize the compatibility of design data with other applications.

- Calculation of fatigue strength

Meet marine design standards by calculating complex stress concentration factors using automated meshing or industry-specific SCF rules. Estimate fatigue wave and wind loads using standard or custom S-N curves.

- Determination and management of structural loads

Define and manage various structural loads and associated constraints for all offshore structures. Changing the parameters for checking code and loads before analyzing stresses. Improving the overall design quality and integrity of offshore structures.

- Compliance with standards of design of offshore structures

Enforce design compliance with built-in validation. Filter results for critical conditions. Optimize design and customization to meet current and past international standards including API, AISC, EC, ISO, DNV and Norsok.

- Analysis of constructions stress

Import marine structure data, perform static structural analysis with automatic model generation. Inspection of steel structures under various loading conditions. Generate detailed stress analysis reports. Improving the integrity, quality of offshore design and compliance with design standards.

- Automation of technical processes of offshore structures

Manage different types of analyzes with customizable templates while working with a common design model. Automatic data transfer at every stage of the project. Simplified management of large and complex models for project research with automated workflows.

- Generating Stress Analysis Reports

Generate graphical comprehensive analysis reports while monitoring offshore structures using the finite element method. Display plots of shear forces and bending moments along with curved shapes for static and dynamic analysis. Create animations of curved shapes of models. Generation of reports on color contours of plane stresses.

- Design and analysis of pile constructions

Manufacturing of high quality integral offshore pile structures. Performing a nonlinear analysis of the interaction of soil, pile and structure of fixed structural models with various rigidly fixed supports.

- Optimizing the design of offshore сonstructions

Streamline your offshore design with an integrated design and analysis environment. Conduct nonlinear analysis along with dynamic response analysis to all offshore wind, wave and seismic loading conditions to optimize structural design. Validate and analyze fatigue cycles to ensure the integrity of the offshore design.

Offshore Platforms

________________________________________________________

Activity area:

- design of fixed offshore platforms;

- design of pier platforms;

- design of dam platforms;

- design of helicopter decks on offshore installations;

- design of facilities for drilling and operation of onshore oil and gas wells;

- servicing, overhaul, reconstruction and upgrading of the said facilities;

- design of removal of decommissioned marine installations;

- design and servicing of floating drill rigs;

- also design of any kind of marine installations;

- Note: fixed offshore platforms, pier platforms and dam platforms are intended for drilling of oil and gas wells, oil and gas storage facilities, high pressure compressor stations etc.

Projects:

- Design of Deepwater Platforms for Drilling of Production Wells at 80-190 m sea depth (Gunashly and Garabag Fields)

- Design of Deepwater Platform for Drilling of Production Wells at 50-60 m sea depth (Umid Field)

- Design of Offshore Platforms for Drilling of Production Wells at 30-50 m sea depth (Oil Rocks and Bulla Field)

- Design of Offshore Platforms for Drilling of Production Wells at 5-30 m sea depth (Oil Rocks, Absheron, Sand Island, 8 march, Bulla, Bahar etc.)

- Construction of Pier Platforms (Oil Rocks, Absheron, Nariman Narimanov, Sand Island)

- Drilling of Production Wells Onshore Installations.

Software applications used for operations:

- AutoCAD

- Staad Pro

- GT STRUDL

- Math Cad

- 3D Max

- E3D AVEVA

- Excel

- NAVISWORKS

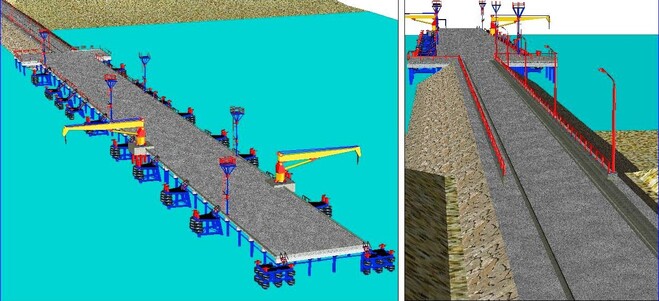

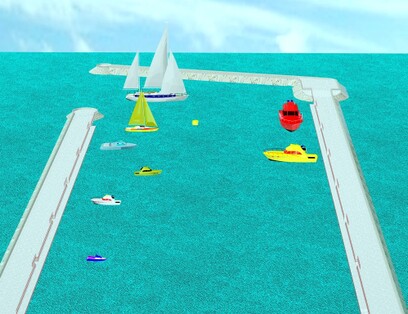

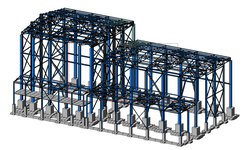

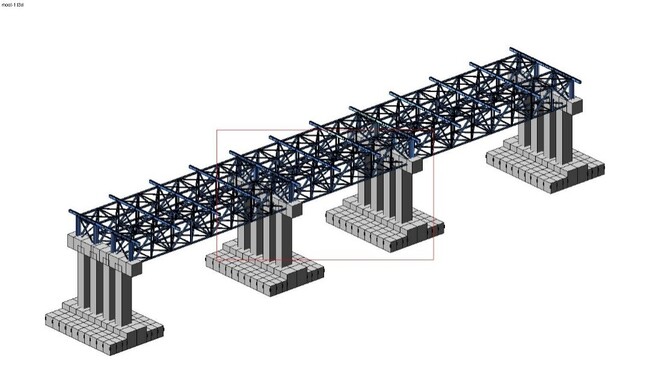

Offshore Overpasses

________________________________________________________

Activity area:

- Design of capital construction and reconstruction of sea piers;

- Design of capital construction and reconstruction of pier platforms;

- Design of capital construction and reconstruction of berth and harbors;

- Design of capital construction and reconstruction of piers for tankers;

- Design of dams and breakwaters.

Projects:

Construction of replacing pier between BM 2 and cargo bridge in Oil Rocks - 2006-2008

Expansion of SKS (compressor station)-2 in Oil Rocks –2008

Mooring berth (Pirsaat cargo bridge - 2013)

Port complex for yachts (Turkan Marina - 2015)

Construction of new piers between sites (platforms) in Oil Rocks field

Construction of NIHP and Tanks Farm in “Oil Rocks” field of “28 May” OGPD

Reconstruction of the helideck and passenger waiting building in Oil Rocks and the area

where the building is located - 2019

Software applications used for operations:

- AutoCAD

- AVEVA Everything 3D

- STAAD Pro.

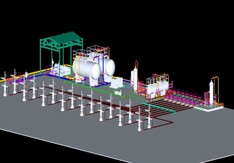

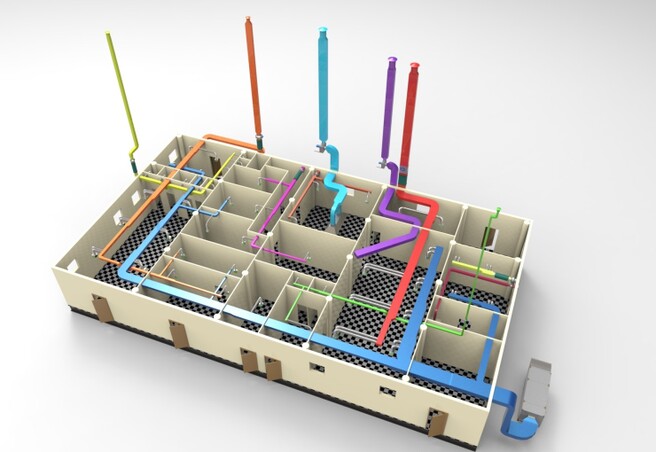

Оil and Gas Field Improvement

________________________________________________________

Activity area:

The department implements the following projects of the production technology department of projects:

- Designing of oil storage facilities;

- Designing of gas storage;

- Designing of separation system;

- Designing of produced water treatment and utilization system;

- Designing of oil metering units;

- Designing of gas metering units;

- Designing of regulating units;

- Designing of gas distribution point;

- Designing of oil depots;

- Designing of oil treatment system;

- Designing of gas treatment system;

- Designing of oil pump stations;

- Designing of produced water pump stations;

- Designing of chemical reagent system;

- Designing of tanks;

- Designing of drainage system;

- Designing of candle system;

- Designing of manifold blocks;

- Designing of process pipelines;

- Designing of heat exchangers.

The department carries out any offshore and onshore projects related to the improvement of oil and gas fields, collection, preparation and transportation of oil and gas.

The department develops production technology sections of new and existing oil and gas fields, improvement, reconstruction, modernization of technical facilities, overhaul of facilities.

Oil and gas separators, buffer tanks, oil pumping stations, oil manifolds, gas lift system for oil production, oil metering units are designed for offshore and onshore oil transportation.

Gas separators, gas manifolds, gas metering unit, gas system, methanol block are designed for offshore and onshore gas transportation.

Designs three-phase separators, oil tank farm, reservoir water tank park, oil pump station, water pump station. Designs high-pressure submersible pumping stations (HPS) to maintain stable offshore and offshore oil production.

Designs the technological process of gases injected and taken to underground gas storages.

Oil and gas separators, buffer tanks, oil pumping stations, oil manifolds, gas lift system for oil production, oil metering units are designed for offshore and onshore oil transportation.

Gas separators, gas manifolds, gas metering unit, gas system, methanol block are designed for offshore and onshore gas transportation.

Designs three-phase separators, oil tank farm, reservoir water tank park, oil pump station, water pump station. Designs high-pressure submersible pumping stations (HPS) to maintain stable offshore and offshore oil production.

Designs the technological process of gases injected and taken to underground gas storages.

Projects:

Onshore

- “Construction of gas distribution point in Garadagh Underground Gas Storage Storage” of Gas Storage Operations Department of Azneft Production Association - 2008

- Reconstruction of the Kalmaz Underground Gas Storage Facility of the Gas Storage Operations Department of the Azneft Production Association - 2010

- Construction of storage and transportation systems of produced products on the field No. 1 of" Bibiheybatneft "Oil and Gas Production Department, improvement of the field" - 2010

- “Construction of Oil Storage Area of Oil and Gas Production Area No. 3 and 4 in Buzovna area and Complex Oil and Water Preparation and Injection Station” of Oil and Gas Production Department named after HZ Tagiyev - 2010

- “Reconstruction of collection-transportation system” of Absheronneft OGPD - 2014

- Designing of new modular Gas Distribution Station at 38 GDU belonging to Absheron MGPA – 2015

- “Construction of new low and high pressure gas separation facilities in Dashgil Central Reservoir Park” of Oil and Gas Production Department named after N.Narimanov -2016

- Construction of a new gas distribution point to increase the active gas volume of the Kalmaz underground gas storage to 1.5 billion m3 – 2018

- Construction of a new gas distribution point to increase the active gas volume of the Garadagh underground gas storage to 2.0 billion m3 by the Gas Storage Operations Department - 2018

- "Gathering of low-pressure gases in Siyazanneft's Oil and Gas Production Area No. 3 and delivery to nearby settlements" - 2018

- “Construction of a new centralized oil collection point, oil transportation system and establishment of a complete closed collection, treatment and utilization system of produced water” object in the territory of OGPD No. 1 of Balakhani Operating Company LTD branch in the Republic of Azerbaijan- 2019

Offshore

- “Designing of oil and gas transportation system of“ Umid field” object – 2012

- Post-Drilling İmprovement of Stationary Base No. 620 in Darwin Bank Field - 2013

- Construction of deep water jacket No. 7 in Gunashli field - 2014

- “Construction of gas storage point No. 2A in Bulla-Deniz field” Oil and Gas Production Department named after N Narimanov – 2015

- “Construction of an oil storage point with expansion of field No. 290 and transportation of products to the shore” in ”Absheronneft Oil and Gas Production Department – 2015

- Construction of Enlarged Oil Storage Station No. 2A in Oil Rocks – 2016

- Reconstruction of deep water jacket No. 10 in Gunashli field - 2016

- " Construction of a new Enlarged Separation Plant in Oil Rocks" of 28 May, Oil and Gas Production Department – 2017

- Reconstruction of deep water jacket No. 1 in "Karabakh" field – 2018

- Construction of deep water jacket No. 50 for drilling 16 production wells in West-Absheron field of "Absheronneft" OGPD -2020

Software applications used for operations:

- AutoCAD

- AVEVA E3D

- Autodesk Plant 3D

- HYSYS

- PRO 2

- MS Office

Reporting programs developed by the department:

- to calculate the diameter and wall thickness of the pipe;

- to calculate the flow capacity of pipelines;

- hydraulic report of the pipeline;

- to calculate the mass of pipelines, etc.

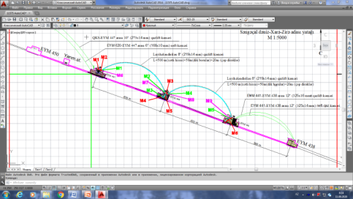

Pipelines

________________________________________________________

Activity area:

- Design of subsea, underground and surface pipelines:

- Selection of subsea ,underground and surface pipelines plan;

- Installation of risers in subsea pipelines and connection to the existing system;

- Development of technology for laying of subsea, underground and surface pipelines;

- Installation of pig receiver at the beginning and end of subsea, underground and surface pipelines ;

- Design of underground and surface pipelines,railways,highways and river crossings ;

- Reporting of subsea, underground and surface pipelines (hydraulic report, strength report, stability report).

Projects:

- "Design of onshore transportation system of products to be produced from Umid-Babek offshore block" - 2020

- “Construction of new transportation line between pier near No. 60 of OGPD named after N.Narimanov and and NYM 1” 2019-2020

- Construction of the main gas pipeline between the 287th km of the “Mozdok-Gazimammad gas pipeline” of the Gas Export Department and the “Sumgayit gas-regulating station branch main gas pipeline” 2019

- "Reconstruction of 57.0-127.4 km section of the Northern Export Pipeline" 2019

- “Construction of a new main gas pipeline between Kenizdag-Sangachal Main Facilities” 2018-ci il

- “Reconstruction of Sangachal BG-Garadagh main gas pipeline” 2017

- “Construction of a new gas pipeline between Sangachal Main Facilities - New Gas Processing Plant” 2017

- “Laying of subsea pipelines between fixed offshore platform No. 57, 23, 38 and pier near No. 290 of Absheronneft ”OGPD” - 2016

- "Construction of external gas supply system for the carbamide plant.” 2016

- “Construction of 90 atm main gas pipeline between Sangachal BQ-47th km-Kalmaz YGA”

- “Construction of a subsea oil pipeline from the “Gunashli ” field deep-water offshore platform 8 of the “28 May” OGPD to the ISG point located in the“ Oil Rocks ” 2015 etc.

Software applications used for operations:

- AutoCAD;

- Caesar;

- Offpipe;

- Autopipe;

- Everything 3D;

- OLGA

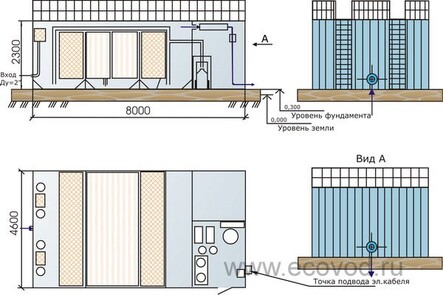

Compressor Facilities

________________________________________________________

Activity area:

- Feasibility study for the construction of compressor stations;

- Design of natural gas collection, processing and transportation systems;

- Design of gas lift and airlift compressor stations;

- Design of compressor stations for main gas pipelines;

- Design of compressor stations for low pressure gas collection;

- Design of compressor stations for underground gas storage facilities;

- Design of air and nitrogen compressor stations for various purposes (mining, factory, etc.);

- Design of periodic water pump stations;

- Design of cooling systems for compressor stations;

- Design of compressed gas cooling systems;

- Design of gas metering points;

- Design of gas pressure control points;

- Design of pipe stand and drainage systems;

- Design of other works referring to compressor facilities, etc.

In addition, the following works can be done:

- Projects on utilization of heat separated from compressor units;

- Projects on gathering and suppling hydrocarbon gases to consumers;

- Design of gas distribution points;

- Design of compressed air supply systems for various profiles (mechanical engineering, light industry, etc.).

- Construction of a new compressor station No. 3 for the Kalmaz Underground Gas Storage Facility -2019

- Gathering of low pressure gases in Siyazanneft Oil and Gas Production Area No. 3 and delivering to nearby settlements" - 2018

- Installation of compressors for low pressure gas collection at platform No 1799, Neft Dashlari - 2017

- Installation of compressor unit in Baku Oil Refinery nitrogen-oxygen facility - 2015

- Construction of low pressure gas collection system at the platform No 1887, Oil Rocks - 2014

- "Reconstruction of compressor station No. 4, Oil Rocks "- 2013

- “Reconstruction of Garadagh Compressor Station No. 2” - 2013

- Construction of Astara Interstate Gas Compressor Station -2010

- "Reconstruction of Kalmaz Gas Compressor Station" - 2010

Software applications used for operations:

- AutoCAD

- AVEVA

- Microsoft Office

Reporting programs developed by the department:

- to calculate the diameter and wall thickness of the pipe;

- for calculation of power of heat exchange apparatus;

- to calculate the required power of compressors;

- to calculate the temperature of the compressed gas in the compressor;

- to calculate the capacity of pipelines;

- to calculate the mass of pipelines, etc.

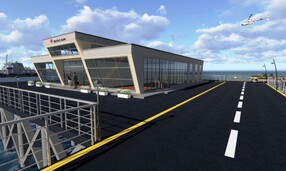

Architecture and Construction

________________________________________________________

Activity area:

- The main task of the department is to design industrial, civil and public buildings.

- Design of industrial facilities: offshore and onshore oil -gas production, oil separation points planning, design of oil separation tank foundations, architectural solution in desgin of control buildings, pumping stations, boilers, transformer substations, production workshops, etc;

- Design of civil facilities; including multistory apartment houses, residential blocks, dormitories, hotels, parks and squares;

- Design of public buildings: administrative and project buildings, educational buildings, schools, kindergartens, cultural and educational clubs, concert halls, libraries, shopping centers, utilities, laundry, small facilities, sports complexes, stadiums, etc. designing;

- Project work for the reconstruction, expansion and overhaul of existing enterprises, as well as author's control over the facilities under construction;

Projects:

- Rest house in Zagulba settlement "Overhaul of the seaside mooring bridge in Zagulba settlement" Rest house

- Caspian Sea Oil Fleet . Marine Life Protection Training Center of Caspian Sea Oil Fleet " Construction of a specialized covered pool".

- Department of Ecology " Expansion of the waste center. Production building for "VakuDry "sludge processing plant

- Oil Gas Scientific Research Project Institut, Experimental Laboratory Building

- OGPDnamed after N.Narimanov 240-beds hospital in Lokbatan settlement

- Reconstruction works on the fuel oil trestle located on the territory of the 11th area of the Heydar Aliyev Oil Refinery

- Surface transition node of new pipelines and existing underground pipelines in Babek avenue.

- SOCAR/ training building

- Oil Refinery named after Heydar Aliyev.

- Reconstruction of the flue gas duct of the 4 № production 43 № gradual coking plant. Flue gas duct H=120m

- 12-storey residential building in Badamdar settlement

Software applications used for operations:

- AutoCad

- Archicad

- 3dmax

- Lira

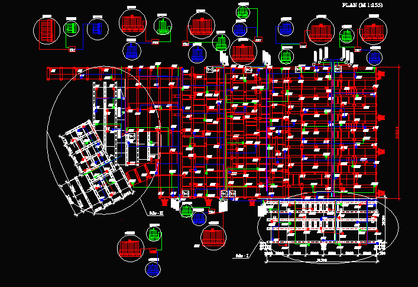

Prospecting and Surveying

________________________________________________________

Activity area:

The main area of activity of the department is the preparation of topographic plans of various scales along the oil-gas-water-electric-sewage lines of the areas where the facilities will be located on land areas, and the exploration of engineering-geological-hydrogeological conditions of these areas-lines, and the investigation of negative processes to which engineering-geological-hydrogeological conditions will be exposed.

The department conducts in-house research based on the results of hydrographic, engineering-geological field work, laboratory research implemented at sea by the Department of Geophysics and Geology, and provides designers with the necessary information and parameters.

The schedule of topographic and geodetic works is compiled on the basis of SOR (statement of requirements) received by the department. The scope of work to be done, the degree of difficulty, the methods of work are specified. According to the terms of reference of the LPE (lead project engineer), a topographic plan of construction sites for power and pipelines, road lanes at scales of 1: 500, 1: 1000, 1: 2000 is developed.

The results of field measurements are calculated at lab office, and plans and schemes are developed on computers using appropriate programs.

Once the electronic digital topographic plans have been developed, they are checked (in the field and lab), placed on sheets of the ordered scale, and sent to the LPE.

UGB-001 mobile drilling rig mounted on Kamaz truck is used for engineering-geological works. Depending on the terms of reference, wells of different depths are drilled using this unit, soil samples and groundwater samples are taken from the wells in accordance with the instructions, and the samples are studied in the geotechnical-chemical laboratory and a report is made as a result of in-house research. This report presents to the designers the load-bearing resistance of the subsoil at the facility and many other indicators.

During the drilling, the geologist fills the drilling log outside and hands it over to the lab team. The drilled wells provides data about the rocks, ie the names of the rocks are determined.

During field work, the geologist drills wells along gas pipelines, water pipelines, sewerage, power transmission lines and measures the resistance of rocks with electrical resistance gauge to a depth of 1 m near each well. The values measured outside are determined by the specific resistance in-lab studies.

According to the results of laboratory analysis, a conclusion is drawn about the construction site.

After drilling the wells, hydrogeological observations are carried out in the wells.

Projects:

- "Construction of new tanks for storage of motor gasoline in the commodity park of production No. 7"

- Surface construction for drilling of production-injection wells No. 496, 497, 498, 499, 600, 601, 602, 603, 604 in Garadagh area of the Gas Storage Operations Department

- Reconstruction of Dashgil oil gathering station of OGPU named after N.Narimanov"

- Construction of the main gas pipeline between the 287th km of the "Mozdok Gazimammad gas pipeline" of the "Gas Export" Department and the "Sumgayit QTM branch of main gas pipeline".

- Surface construction for drilling of production-injection wells No. 605, 606, 607, 608, 609, 610, 611, 612 and 613 in Garadagh area of the Gas Storage Operations Department.

- Construction of a new centralized oil gathering station, oil transportation system and establishment of a fully closed collection, treatment and utilization system of produced water in the territory of OGPU No. 1 of the branch of Balakhani Operating Company LTD in the Republic of Azerbaijan.

- Installation of gas treatment units at 69 gas distribution stations attached to the Gas Export Department. (Allahyarli)

- "Design of an onshore transportation system for products from the Umid-Babek offshore block"

Software applications used for operations:

- AutoCAD

- Microsoft Office

- Trimble Buzness Center

- Trimble Geo Office

- ArcGİS

Energy and communication systems design

________________________________________________________

Activity area:

- Design of 35/10/6/0,4 kV substations

- Design of single-line schematic circuit diagrams of 35/10/6/0,4 kV spots (cells)

- Development of request forms for 35/10/6/0,4kV spots (cells)

- Creation of electrical grid according to master plan

- Design of schemes for the compatibility of the electrical part with the automation (I& A).

- Electrical supply of Deep Water Jackets and Permanent offshore platforms, pier and pier platforms, design of all types of electric lighting lines, preparation of cable routes plan

- Selection of power and current transformers according to design power, preparation of questionnaires and compilation of reports.

- Calculation of active and reactive energy and selection of proper equipment according to required power.

- Selection of diesel power stations (generators) for emergency and operating modes and design of network connection schemes.

- Lightning protection (drawing-up of plans and compilation of reports)

- Laying of 35/10/6 and 0,4 kV overhead transmission lines (underground and subsea cable lines, overhead transmission lines),drawing-up of plans and compilation of reports.

- Drawing-up of plans for internal, external, emergency, evacuation lighting of buildings and structures designed on the sea and onshore, as well as, plans for the lighting of piers, parks, streets and highways, compilation of reports.

- Development of the grounding scheme (working grounding, static load protection) and reporting.

- Design of telecommunication systems.

- Design of evacuation warning systems (PQGA).

Projects:

- Expansion of the Astara compressor station 2010

- "Expansion of the corporate network at SOCAR enterprises" 2012

- "Laying of a 35 kV subsea cable line from QTES 48 at the “28 May” OGPD in Oil Rocks to Chilov Island" - 2013

- Construction of a new oil gathering station at “Absheronneft” OGPD 2013

- Construction of DWJ No 7 in “Gunashli” field of “28 May” OGPD. 2014

- Department of Ecology – Expansion of "Waste Center” 2014

- Reconstruction of 35/6 kV transformer substation No. 365 of “BEOGL” company with equipment. 2015

- "Construction of a fixed drilling offshore platform No. 18 for drilling 1 exploration and 4 production wells at the Bulla-Deniz field" OGPU named after N.Narimanov” 2016

- “Construction of a new transformer substation for electric power supply of ”5 and 6 raw material stock” (park) in the Oil Refinery named after Heydar Aliyev“ 2016

- Construction of a new substation No. 1A with a capacity of 10 / 0.4 kV at the "Garadagh" QKS of the Operating Gas Storage Facilities department. 2016

- "Investigation of the state of lightning protection of the gas supply system (KS, QPS MQKS, AQPS, QTM, QÖQ), buildings and structures on the balance of the Gas Export Department and preparation of a conclusion" 2017

- Construction of DWJ No. 1 in “GARABAGH” field. 2018

- "Construction of a new compressor station No. 3 to increase the active gas volume in the Kalmaz UGS facility to 1.5 billion m3" of the Operating Gas Storage Facilities department. 2018

- Overhaul of the power supply of the jackets in the "Guneshli" field. 2019

- Reconstruction of electrical power system in "8 Mart", Xare-Zire fields, in piers and pier platforms of OGPD named after “N.Narimanov”. 2019

- Construction of 5 new tanks instead of 10 fuel tanks located in the tank farm No 1 of the production facility No 7 in the Heydar Aliyev Oil Refinery. 2019

- Feasibility study of the project " field facilities installation of the Khazar field" of the "Pearls" block (Power supply, Communications and warning/alarm system) 2019

- Construction of a land plot No. 1240 for drilling 10 production wells at the Pirallahi field of the Absheronneft OGPD. 2019

- BHBTDL "Open Joint Stock Company" - Reconstruction of Baku Hovsan International Trade Port " 2020

- Design of facilities for storage and shipment of liquefied petroleum gases (LPG) at the terminal in Kulevi "

- Construction of a fixed-drilling offshore platform No. 50 for drilling 16 additional production wells at the “West Absheron” field. (order 11641) 2020

- Expansion of the fixed-drilling offshore platform No. 57 for drilling 10 additional production wells in the “West Absheron” field of the Absheronneft OGPD 2020

- "Automatic connection to the network, uninterruptible power supply (UPS) and diesel generators for continuous power supply of the Garadagh gas compressor station" of the GAII (Operating Gas Storage Facilities Department) 2020

- Design of the UBOC Dashgil-2 terminal of the Umid Babek Operating Company, 2020 (underway)

Software applications used for operations:

- AutoCAD

- DIALux

- MS Office

Instrumentation and automation

________________________________________________________

Activity area:

- Design of automation of technological processes in oil production;

- Design of automation of technological processes in oil and gas refining;

- Design of automation of technological processes of oil and gas transportation and storage;

- Design of automation of technological processes in compressor stations;

- Design of automatic fire detection systems;

- Design of automatic fire alarm system;

- Design of automatic water fire extinguishing system;

- Design of automatic foam fire extinguishing system Avtomatik köpük ilə yanğınsöndürmə sisteminin layihələndirilməsi;

- Design of automatic gas fire extinguishing system;

- Design of automatic gas fire extinguishing system;

- Design of automatic gas detection system;

- Design of automatic gas alarm system;

- Design of automatic emergency management system in case of fire and gas alarm;

- Design of video surveillance systems;

- Design of structural cable network systems;

- Design of heating, ventilation and cooling systems.

Projects:

- Construction of deep water jacket № 7 in “Gunashli" field (correction) - 2014;

- Construction of SDO No 12 for drilling 5 wells in Bulla deniz field of OGPD named after N. Narimanov – 2016;

- Setting (correction) of an automatic fire extinguishing system on No 3 jacket of Gunashli field of 28 May OGPD - 2016;

- Construction of SDO No 18 for drilling 1 exploration and 4 production wells in Bulla deniz field of OGPD named after N. Narimanov – 2017;

- Construction of new No3 compressor station for Galmaz UGS -2019

- Establishment of automatic foam fire extinguishing system in Commodity Tank Park No 5 and 6 to ensure timely and safe reception of products from the Absheron” field by the existing systems in the territory of “Oil Rocks” OGPD - 2019;

- Construction of new comperssor station in Chilov island 28 May OGPD - 2020;

- Collection and delivery of low pressure gases at Siyazanneft's Oil and Gas Production Area No. 3 to nearby settlements - 2018

- Installation of compressors for low-pressure gas collection at Oil Rocks, site 1799 - 2017

- Reconstruction of the collection and transportation system of Absheronneft OGPD - 2013

- Implementation of an automated foam fire extinguishing system in commodity tank park No 11 at Dubendi oil storage point - 2012

- Hajigabul KS automatic control system -2014

Software applications used for operations:

- AutoCAD

- “POTOK-RU”

- MS Office

Automatic Control Systems and Information Technologies

________________________________________________________

________________________________________________________

Activity area:

- To design Automated Control Systems (ACS) for oil, gas, chemicals and energy industries;

- To provide software and hardware design and development on the Programmable Logic Controller (PLC) basis;

- To develop and maintain ACS and Supervisory Control and Data Acquisition (SCADA) on the Programmable Logic Controller basis aligned with engineering, information and international standards at oil and gas facilities and provide research and technical maintenance of these applications and software;

- To apply the latest ways and means of information sharing (wireless telemetry - radio, GSM / GPRS; web monitoring) to the development of distributed control systems (DCS);

- To develop applications for generation of methodological and technological reports required in the oil and gas industry.

Projects:

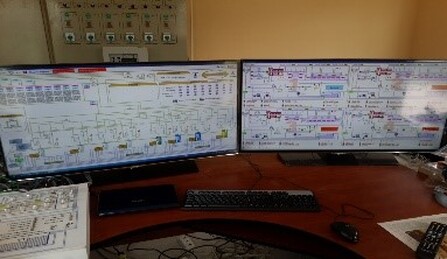

Remodeling of the Hajigabul Compressor Station Automated Control System – 2015

Before reconstruction:

After reconstruction /Operator’s Automated Workstation

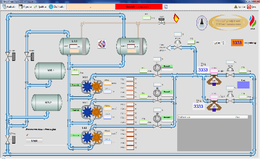

Remodeling of the Collection and Transportation System of the “Absheronneft” OGPD -2017

“Construction of Compressor Station# 3 to increase the active gas volume of the Kalmaz Underground Gas Station of the Gas Storage Facilities Operations Division up to

1.5 billion m³” – 2019

Construction of the New Oil Pump Station on the Deep Water Gunashly Platform #8 of “28 May"

OGPD – 2019

Construction of the New Oil Pump Station on the Deep Water Gunashly Platform #13 of

“28May" OGPD – 2019

Development of emergency shut-down and automated control system for 10 QKN type facilities on the compressor station#1 located in Garadag -2020

AutoCAD, Microsoft Word, Microsoft Excel, Microsoft SQL Server, MicrosoftVisual Studio, GX Works2 (Mitsubishi Electric Automation), GX Works3(Mitsubishi Electric Automation),GX IEC DeveloperHMI(Mitsubishi Electric Automation),GT Designer 3 (GOT 1000, GOT200, GS HMI series),Easy Builder Pro (Weintek Easy View HMI).

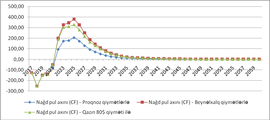

Projects economic asessment

________________________________________________________

Activity area:

- Feasibility study of projects developed by NIPIENGINEERING

- Oil and gas production: Calculation of economic efficiency in connection with the use of new equipment and technologies in oil and gas production.

- Geology: Calculation of reserves of oil and gas fields and economic assessment of the development of oil and gas fields

- Completed work on free topics

Projects:

- Feasibility study for the construction of a plant for the production of iodine and distilled water grade “ч” from formation waters - 2015

- Feasibility study of the construction of the Astara Interstate gas compressor station - 2011

- "Feasibility study of the reconstruction of the Galmaz gas compressor station" - 2011

- "Feasibility study of the construction of a low-pressure gas collection system in site No. 1887 at Oil Rocks," - 2014

- Feasibility study of the construction of a gas pipeline between the Igdir (Republic of Turkey) -Sadarak-Nakhchivan gas distribution point to meet the needs of the Nakhchivan Autonomous Republic in natural gas - 2011

- Feasibility study of the development of the “Umid” field -2016

- Economic assessment of the object for "Transportation of products to be extracted from the “Gosha dash” field - 2017

- Feasibility study of the construction of deep water offshore platform No. 7A for drilling 4 production wells in the Guneshli field - 2017

- Assessment of the object "Transportation of products to be produced from the “Babek” field - 2017

- Economic assessment of development parameters of the "Karabakh" field - 2018

- Feasibility study of the Khazar field (Republic of Kazakhstan) development project - 2019

Software applications used for operations:

- MS Office

- calculation of capital investments CAPEX

- calculation of operating costs OPEX

- calculation of income from the sale of goods

- determining the tax

- calculation of cash flow CF

- calculation of the net present value NPV

- determination of the pay back period PBP; DBP

- calculation of internal rate of return İRR

- determination of the profitability index of the project PI

Calculation programs developed by the department:

Corrosion protection

________________________________________________________

Activity area:

Corrosion, erosion and microbiological erosion protection of onshore and offshore oilfield equipment, hydraulic structures, platforms and piers, oil refining and petrochemical facilities, subsea, underground and surfase pipelines and other communications:

- by bactericides (biocides) and inhibitors,

- by varnishes and composite materials,

- scientific and research and design work in the field of electrochemical protection.

Projects:

- Construction of new pump stations to maintain stable reservoir pressure at the Guneshli field of the "28 May" OGPD, 2018.

- Overhaul of “Neftgastikinti” trust Zykh-1 mooring bridge and the entrance pier of the Neftgaztikinti trust, 2018.

- Construction of land plot No. 1240 for drilling 10 production wells at Absheron oil OGPD.

- Reconstruction of the Kalmaz UGS of gas storage department, 2018.

- Construction of a new main gas pipeline between Kanizdag and Sangachal main facilities of the Gas Export department, 2018.

- “Reconstruction of the Dashgil oil-gathering point" of OGPD named after N.Narimanov was carried out in 2018-2019.

- FEED (initial phase) of the Absheron EPS project for JOCAP joint venture established between SOCAR and TOTAL, was implemented in 2017-2018.

- Construction of Deep water Jacket No. 1 in the Karabakh field”of “28 May” OGPD was implemented in 2017-2018.

- Installation of 2 additional gas turbine generators of "Oil Rocks" OGPD, expansion of the QTİES was completed in 2019.

- “Design of the onshore transportation system of products from Umid, Babek offshore block" was implemented in 2020.

- Construction of a new D720mm main gas pipeline between Garadagh-Digah GDS for reliable gas supply of Baku was completed in 2020.

Software applications used for operations:

- AutoCad

- Microsoft Office

- Visual Basic

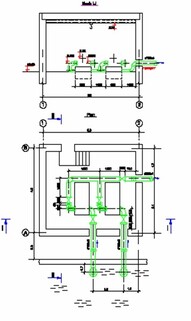

Sanitary Works Department

________________________________________________________

Activity area:

- Design of water and sewage pipelines.

- Design of fire pipelines.

- Design of water and sewage pump stations.

- Design of water treatment plants.

- Design of gas pipelines.

- Design of heat sources and networks.

- Design of heating, ventilation and air conditioning systems.

Projects:

- Construction of Fixed Offshore Platform No. 18 in “Bulla-deniz” field of OGPD named after N.Narimanov. Execution date: August 08, 2017

- Pre FEED stage of “Construction of Deep offshore Pllatform No. 1 in“ Garabagh ”field of“ 28 May OGPD “ facility. Execution date: March 15, 2018

- Design of UBOC Dashgil-2 Terminal. Execution date: August 1, 2020

Software applications used for operations:

- Autodesk Revit MEP

- FIREX Pro

- HAPCarrier

Ecology Department

________________________________________________________

Activity area:

The following scientific-research works and projects are studied, developed and approved:

- Environmental protection section of projects

- Ecological section of projects

- Sanitary protection zone document

- Regulatory document on the acceptable flow

- Regulatory document on the acceptable disposal limit

- Hazardous waste certificates

- Ecological certificates

- Water industry certificates

- Document on the assessment of environmental impact

- Scientific-research works related to Ecology

- Preparation and study of proposals for the use of alternative energy sources and other energy-saving technologies at facilities.

Projects:

- Connection of the jacket and connecting pier to the existing system near the "Oil Rocks" tanker berth for the development of the primary well of the TOTAL Absheron field;

- Construction of Deep Sea Jacket No. 7 at the Guneshli field; 2011

- “Construction of underwater gas lift lines between 447-444 and 444-441 sites of OGPD named after N.Narimanova 2020

- Creation of a new oil transportation system for the centralized oil gathering station of the 1st branch of Balakhani Operating Company LTD in the Republic of Azerbaijan and creation of a collecting, cleaning and utilizing system for produced water in a completely closed system; 2019

- "Collection of low-pressure gases at oil and gas production area No. 3 of "Siyazanneft" OGPD and delivery to nearby settlements" 2018

- Waste Center Expansion (I start-up and commissioning) 2012

- Construction of a high-pressure pipeline transportation system at Shirvan QPS for associated gas produced at the Kursangi field of “Salyan OIL LTD” Operating Company; 2017

- Reconstruction of the Hovsan Canal 2018

- Preparation of a schematic map for redefining the sanitary protection zone of the Oil refinery named after N. H. Aliyev 2019

Software applications used for operations:

- Environmental engineer (Version 2.55)

- Accidents on oil pipelines

- AZS- Environmental engineer (Version 1.6)

- АТП- Environmental engineer (Version 3.0)

- Oil combustion

- Wood working (Version 1.0)

- Diesel (Version 2.0)

- Instruction on WAH

- Boiler stations (Version 3.4)

- Surface finish (Version 2.0)

- Metalwork (Version 2.0)

- APG- Environmental engineer (Version 1.0)

- РВМ- Environmental engineer

- РВУ- Environmental engineer for Windows

- РНВ- Environmental engineer (Version 2.1)

- Welding (Version 2.1)

- Guide for substances (Version 4)

- Bulk material

- Flare (Version 2.0)